Creating a Control Chart in Excel: A Step-by-Step Guide

A control chart, also known as a Shewhart chart or process-behavior chart, is a valuable tool for monitoring and controlling processes. It helps identify variations in data that can indicate special-cause or common-cause variation, allowing you to take appropriate actions to improve process performance. In this comprehensive guide, we will walk you through the process of creating a control chart in Excel, empowering you to visualize and analyze your data effectively.

Step 1: Gather and Prepare Your Data

Before you begin creating your control chart, ensure you have the necessary data. This typically includes a dataset with two columns: one for the sample number or time and another for the measurement or value you want to analyze. Your data should be organized in a tabular format, with each row representing a sample or measurement point.

Here's an example of how your data might look:

| Sample | Measurement |

|---|---|

| 1 | 12.5 |

| 2 | 13.2 |

| 3 | 11.8 |

| 4 | 12.9 |

| ... | ... |

Step 2: Calculate Control Limits

Control limits are essential components of a control chart as they help identify when your process is in control or when special causes of variation are present. There are several methods to calculate control limits, but one of the most common is the 3-sigma rule, which uses the mean and standard deviation of your data. Here's how you can calculate the control limits:

- Calculate the mean of your measurement data.

- Calculate the standard deviation of your measurement data.

- Determine the upper control limit (UCL) using the formula: mean + (3 * standard deviation).

- Determine the lower control limit (LCL) using the formula: mean - (3 * standard deviation).

You can use Excel's built-in functions to perform these calculations. For example, you can use the AVERAGE function to calculate the mean and the STDEV.S function to calculate the standard deviation. Once you have the mean and standard deviation, you can manually calculate the control limits or use Excel's AVERAGE and SUM functions to calculate the UCL and LCL.

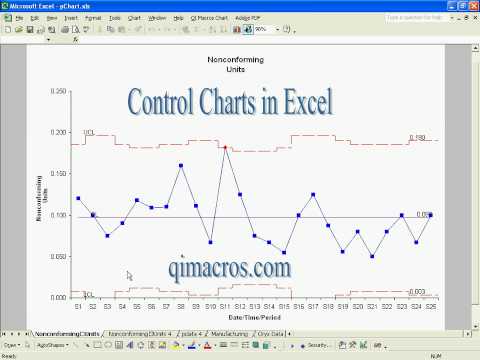

Step 3: Create the Control Chart

Now that you have your data and control limits calculated, it's time to create the control chart. Follow these steps:

- Select the column containing your measurement data.

- Click on the Insert tab in the Excel ribbon.

- In the Charts group, click on the Insert Scatter (X, Y) or Bubble Chart icon.

- Choose the Scatter with Smooth Lines and Markers chart type.

This will create a basic control chart with your data points plotted as markers and a smooth line connecting them.

Step 4: Add Control Limits to the Chart

To enhance the visualization and analysis of your control chart, it's crucial to add the control limits you calculated in Step 2. Here's how you can do it:

- Right-click on the chart and select Select Data.

- In the Select Data Source dialog box, click on the Add button.

- In the Edit Series dialog box, enter a name for the control limits series (e.g., "Control Limits").

- For the Series X values, select the column containing your sample numbers or time values.

- For the Series Y values, select the cell containing your upper control limit (UCL) value.

- Click OK to add the UCL series to the chart.

- Repeat the process to add the lower control limit (LCL) series to the chart.

Your control chart should now display the control limits as horizontal lines, helping you identify any points that fall outside these limits.

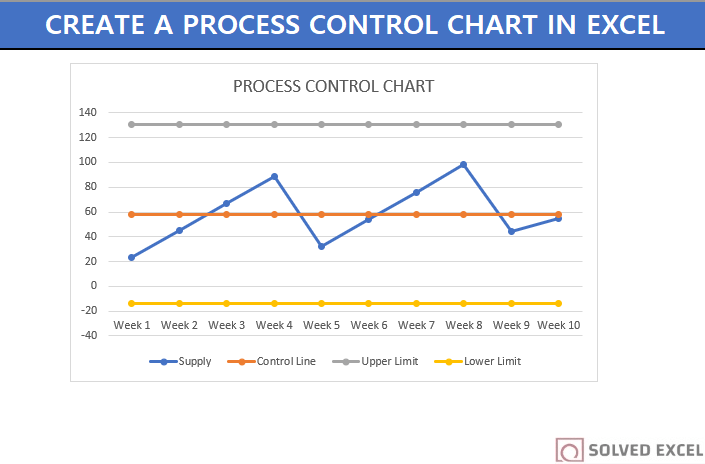

Step 5: Customize and Enhance Your Control Chart

To make your control chart more visually appealing and informative, consider the following customization options:

- Change Marker Styles: Right-click on the data points and select Format Data Series. Here, you can change the marker size, shape, and color to make them more visible.

- Add Trendline: If you want to visualize the overall trend in your data, you can add a trendline to the chart. Right-click on the data series and select Add Trendline. Choose the type of trendline (e.g., linear, exponential) that best fits your data.

- Label Control Limits: You can add labels to the control limits to make them more prominent. Right-click on a control limit line and select Add Data Labels. Choose the desired label options.

- Apply Chart Styles: Excel offers various chart styles and themes that can enhance the appearance of your control chart. Click on the Design tab and explore the available styles.

Step 6: Interpret and Analyze Your Control Chart

Once your control chart is complete, it's time to interpret and analyze the results. Here are some key points to consider:

- Points Outside Control Limits: If any data points fall outside the control limits, it suggests that there may be special causes of variation in your process. Investigate these points further to identify and address the underlying issues.

- Trend Patterns: Look for any patterns or trends in your data. For example, an increasing or decreasing trend over time may indicate a gradual shift in your process.

- Random Variation: If your data points are scattered randomly within the control limits, it indicates that your process is in statistical control. This means that any variations are due to common causes and are inherent to the process.

By analyzing your control chart, you can gain valuable insights into the behavior of your process and make informed decisions to improve its performance.

Conclusion

Creating a control chart in Excel is a powerful way to visualize and analyze process data. By following the steps outlined in this guide, you can effectively monitor and control your processes, identify areas for improvement, and make data-driven decisions. Remember, a well-constructed control chart is a valuable tool for process improvement and quality management.

What is a control chart used for?

+

A control chart is used to monitor and control processes by visually displaying data over time. It helps identify variations in the process and distinguish between common-cause and special-cause variation.

Can I use a different method to calculate control limits?

+

Yes, there are various methods to calculate control limits, such as the moving range method or using historical data. Choose the method that best suits your data and process.

How often should I update my control chart?

+

The frequency of updating your control chart depends on the nature of your process and the data collection frequency. It’s recommended to update the chart regularly to stay current with process performance.

What should I do if my data points fall outside the control limits?

+

If your data points fall outside the control limits, it indicates that there may be special causes of variation. Investigate these points further to identify and address the underlying issues.

Are there any limitations to using control charts in Excel?

+

While Excel provides a convenient way to create control charts, it may have limitations for complex analysis or large datasets. Consider using specialized statistical software for more advanced control chart analysis.