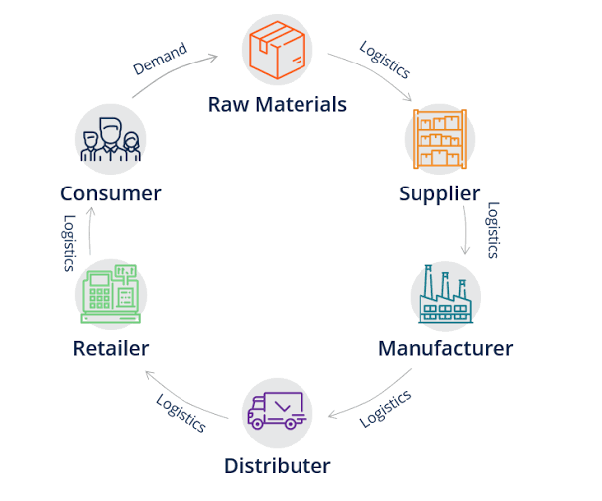

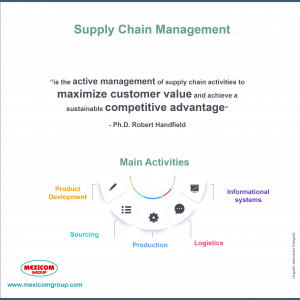

Supply Chain Management (SCM) is a crucial aspect of modern business operations, ensuring the efficient flow of goods and services from raw materials to end consumers. It involves a complex network of processes, people, and resources, all working together to meet customer demands while optimizing costs and maintaining a competitive edge.

In today's fast-paced and highly interconnected world, SCM has evolved into a strategic discipline, offering businesses a unique opportunity to gain a significant advantage over their competitors. By effectively managing their supply chains, companies can enhance their operational efficiency, reduce costs, improve customer satisfaction, and ultimately, boost their bottom line.

Understanding Supply Chain Management

At its core, SCM is about managing the movement and storage of raw materials, work-in-process inventory, and finished goods from the point of origin to the point of consumption. It involves a wide range of activities, including:

- Procurement: Sourcing and acquiring the necessary materials, services, and resources to support production.

- Production: Transforming raw materials into finished products through manufacturing or assembly processes.

- Inventory Management: Optimizing the storage and movement of goods to ensure availability while minimizing costs.

- Logistics: Planning and executing the efficient transportation and delivery of goods to customers.

- Demand Planning: Forecasting and analyzing customer demand to align production and inventory levels.

- Supplier Relationship Management: Building and maintaining strong relationships with suppliers to ensure a consistent supply of high-quality materials.

SCM is a complex discipline that requires a deep understanding of various business functions, including operations, finance, marketing, and information technology. It involves coordinating and integrating these functions to achieve a seamless flow of goods and services throughout the supply chain.

The Importance of SCM

Effective SCM can bring numerous benefits to businesses, including:

- Cost Reduction: By optimizing processes and eliminating inefficiencies, SCM can significantly reduce costs associated with production, inventory management, and logistics.

- Improved Customer Service: SCM helps ensure that products are available when and where customers need them, leading to higher customer satisfaction and loyalty.

- Enhanced Operational Efficiency: Well-managed supply chains can streamline operations, reduce lead times, and improve overall productivity.

- Increased Profitability: By reducing costs and improving customer satisfaction, SCM can directly contribute to a company's bottom line.

- Competitive Advantage: Efficient supply chain management can give businesses a strategic edge over their competitors, allowing them to respond quickly to market changes and customer demands.

Key Components of SCM

Supply Chain Management encompasses several key components that work together to achieve optimal results. These include:

Procurement and Supplier Management

Procurement is a critical aspect of SCM, as it involves sourcing and acquiring the materials, services, and resources needed for production. Effective procurement strategies can help businesses negotiate better deals, ensure a consistent supply of high-quality materials, and build strong relationships with suppliers.

Supplier management involves selecting, evaluating, and managing suppliers to ensure they meet the company's quality, delivery, and cost expectations. It also includes developing strategies to mitigate supply chain risks, such as disruptions or shortages.

Production and Inventory Management

Production management focuses on transforming raw materials into finished products efficiently and cost-effectively. This involves optimizing production processes, minimizing waste, and ensuring that products meet quality standards.

Inventory management, on the other hand, involves planning and controlling the levels of inventory to meet customer demand while minimizing holding costs. Effective inventory management strategies can help businesses avoid stockouts, reduce excess inventory, and improve cash flow.

Logistics and Transportation

Logistics and transportation are vital components of SCM, as they involve planning and executing the efficient movement of goods from one point to another. This includes selecting the most suitable transportation modes, optimizing routes, and managing the delivery process to ensure timely and accurate deliveries.

Demand Planning and Forecasting

Demand planning and forecasting are essential for aligning production and inventory levels with customer demand. By analyzing historical data, market trends, and customer behavior, businesses can make informed decisions about production quantities, inventory levels, and pricing strategies.

Information Technology and Data Analytics

Information technology (IT) plays a critical role in SCM, as it enables the collection, storage, and analysis of data from various supply chain processes. IT systems, such as Enterprise Resource Planning (ERP) and Supply Chain Management (SCM) software, help businesses manage their supply chains more efficiently and make data-driven decisions.

Data analytics, on the other hand, allows businesses to gain valuable insights from supply chain data. By analyzing patterns, trends, and relationships within the data, companies can identify areas for improvement, optimize processes, and make more accurate forecasts.

Implementing SCM Strategies

Implementing effective SCM strategies requires a well-planned approach and a deep understanding of the supply chain. Here are some key steps to consider:

1. Define Supply Chain Objectives

Start by clearly defining the objectives and goals of your supply chain. This could include cost reduction, improved customer service, enhanced operational efficiency, or any other strategic objectives that align with your business goals.

2. Map Your Supply Chain

Create a detailed map of your supply chain, including all the processes, people, and resources involved. This will help you identify potential bottlenecks, inefficiencies, and areas for improvement.

3. Analyze Your Supply Chain Data

Collect and analyze data from your supply chain processes to identify trends, patterns, and areas where you can optimize costs, improve efficiency, or enhance customer service.

4. Develop an SCM Strategy

Based on your supply chain objectives and data analysis, develop a comprehensive SCM strategy. This should include specific actions and initiatives to achieve your objectives, such as implementing new technologies, optimizing processes, or improving supplier relationships.

5. Implement and Monitor

Implement your SCM strategy across your supply chain and closely monitor its performance. Regularly review and analyze key performance indicators (KPIs) to ensure that your supply chain is performing as expected and to identify any areas that require further improvement.

Supply Chain Management Challenges

While SCM offers numerous benefits, it also comes with its fair share of challenges. Some of the common challenges faced by businesses include:

- Supply Chain Complexity: As supply chains become more global and interconnected, managing their complexity becomes a significant challenge.

- Demand Volatility: Fluctuating customer demand can make it difficult to optimize inventory levels and production schedules.

- Supplier Relationship Management: Building and maintaining strong relationships with suppliers can be challenging, especially in highly competitive markets.

- Risk Management: Supply chains are vulnerable to various risks, such as natural disasters, political instability, or economic fluctuations. Effective risk management strategies are essential to mitigate these risks.

- Technology Adoption: Keeping up with the latest supply chain technologies and ensuring their effective implementation can be a challenge for many businesses.

Emerging Trends in SCM

The field of SCM is constantly evolving, driven by advancements in technology and changing business dynamics. Some of the emerging trends in SCM include:

- Digital Transformation: The use of digital technologies, such as artificial intelligence, machine learning, and the Internet of Things (IoT), is transforming supply chain operations, enabling greater efficiency, visibility, and control.

- Sustainable Supply Chains: With increasing environmental awareness, businesses are focusing on developing sustainable supply chains that minimize their environmental impact and promote social responsibility.

- Blockchain Technology: Blockchain offers a secure and transparent way to manage supply chain transactions, improving traceability, reducing fraud, and enhancing supply chain visibility.

- Collaborative Supply Chains: Businesses are increasingly collaborating with their suppliers, customers, and partners to optimize supply chain processes and improve overall performance.

- Omnichannel Fulfillment: As customers expect seamless shopping experiences across multiple channels, businesses are focusing on developing omnichannel fulfillment strategies to meet these expectations.

Conclusion

Supply Chain Management is a critical discipline that can significantly impact a business's success and competitiveness. By effectively managing their supply chains, businesses can achieve cost savings, improve customer service, and gain a strategic advantage in their respective industries. While SCM comes with its challenges, the potential benefits make it an essential focus area for businesses looking to thrive in today's dynamic and highly competitive market.

What is the primary goal of Supply Chain Management (SCM)?

+The primary goal of SCM is to ensure the efficient and effective flow of goods and services from the point of origin to the point of consumption, while minimizing costs and maximizing customer satisfaction.

How does SCM contribute to a business’s success?

+SCM contributes to a business’s success by optimizing processes, reducing costs, improving customer service, and providing a competitive advantage. It helps businesses respond quickly to market changes and customer demands, leading to increased profitability and market share.

What are some common challenges faced in SCM?

+Common challenges in SCM include supply chain complexity, demand volatility, supplier relationship management, risk management, and technology adoption. These challenges require careful planning, strategic decision-making, and effective risk mitigation strategies.